- Home

- About Us

- Gift Shop

- Wholesale Shop

- Bespoke Jewellery

- Engraving Services

- Contact Us

- Terms & Conditions

- Commissioned Projects

- Privacy

- GDPR

- F.A.Q

- Design Services

- 3D Scan - Print Service

- Computerised Stitching

- Edge belt stitching

- Branding Services

- Laser Engraving Metals

- Engraving Non Metal

- Rotary Engraving

- Precision Deep Engraving

- Leather Embossing

- Sublimation Printing

- Laser Engraving - Cutting

- Flocked Products

- Ceramic Anti Tarnish Coating

- Electroplating

- Powder Coating

- Coniex Enamels

- Surface Preparation

- Production Services

- CNC Milling

- CNC Machining Service

- Diecutting

- Sewing

- Soldering- Repairs

- Phone-Ipad covers

- Web Belts

- D Ring Belts

- Web belt Buckles

- Webbing For Belts

- Woven Webbing

- Braided Webbing

- Printed Webbing

- Alphabet buckles

- Custom Made Buckles

- Roller Buckles

- Stainless Steel Buckles

- Crystal Buckles

- Sterling Silver Buckles

- Solid Brass Buckles

- Sublimation Buckles

- Pewter Buckles

- Leather Covered Buckles

- Pin Buckles

- Aluminium Buckles

- Plastic Buckles

- ZODIAC Buckles & Gifts

- Vegan Leather

- Vegan Belts

- Leather Hides

- Custom Made Leather Belts

- Suede Belts

- Leather Components

- Leather Straps

- Watch Straps

- Golf Belts

- Golf Accessories

- Carbon Fibre Products

- D Rings

- Sliders

- Trigger Hooks

- Belt Loops Metal

- Belt End Tips Leather

- Belt End Tips Webbing

- Pendants & Charms

- Keyring Components

- Cufflinks

- Split Rings

- Conchos

- Chicago Screws

- Personalised Screws

- End Terminals

- Sam Browne Studs

- Roller Buckle Bar

- Snaffle Bits

- Bag Name Tags

- Boxes

- Pouches

- Font Styles Engraving

|

|---|

|

||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

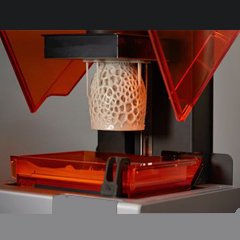

Devanét® 3d scan and print technology investment has come about due to the increased demand for bespoke work involving products where a customer wishes to source from UK manufacture and to have a prototype produced in a short time frame to check size, appearance and functionality. The scanning system is designed to provide detailed high resolution scans with single shot accuracy of between 25-100 microns and smallest scan volume 30 x 30 mm. With the option of two modes auto and fixed,

The 3D print capability has been designed around a maxim of 145 x 145 x 175 mm for high detail the SLA print with a laser spot size of 140 microns and a layer height between 25 and 100 microns. Devanet have 3 SLA printers loaded with different resins to cater for surgical, engineering and jewellery applications. The SLA Printer is used for more detailed jewellery, substantial invesment in the package supplied by Formlabs enables us to produce rapid prototypes, and production quality parts of logod buckles and components - the advantage of being able to produce in various raw materials from standard photopolymner resins to jewellery grades, here are some of the options from our SLA supplier of resins. Devanet has several 3d printers to cope with demand for our customers, with options ranging from standard resins, flexible, surgical, high strength, rigid and dental.

STANDARD GREY RESIN Grey resin is our standard photopolymer which has low creep and moderate elongation at break. it is ideally suitable for concept modelling and functional parts. it is ideal for rapid prototyping for buckles and components, as well as parts that are designed for form and fit testing - where two components need to to work together, for mold masters for plastics, silicones.

CASTING RESIN This amazing product recently became available for direct casting without the need for the intermediate step of producing wax molds and trees. It is ideal for one off prototypes and can be used in the printer to produce an array of parts ready for casting.

It has 20% wax content, posesses features such as zero ash and a clean butn out of the mold essential for good casting results. The resin allows for fine detailed features, smooth finshes typical of SLA prints and above all requires no post cure and is firm enough to handle for trying on and fit tests as well as direct investment casting. This product ideal for complex designs and fine detail components.

RIGID Reinforced with glass to provide high stffness and a polished surface finish, excelllent resistance to deformation and can be used to print thin walls and features in the model. Typical applications would be for jigs, fixtures and tooling, safety buckles for cats, casings and automotrive housings as well as buckles and components for workwear, dog and cat collars as well as guitar straps.

Ceramic A silica filled photo polymer, that after firing and burn out of the photopolymer netowork leaves behind a ceramic part that is resistant up to 1000 degrees centrigrade. The process is considerably more complex than standard resins and requires additional design parameters such as filleted edges and wall thickness control. The design also must cope with shrinkage up to 15 % of the finished part due to the burnt out process so these elements must be carefully considered. Devanét® will undertake special devclopments with Ceramic subject to design parameters.

FLEXIBLE Formlabs flexible resin enables Devanét® to be able to produce components that bend and compress, adding ergonmic and soft feel characteristics that make the 3D prints suitable for a variety of applications encompassing wearable type prototpyes, soft grip handles, cushioning and packaging, stamps. The flexible resin is designed to support print resolutions between 50 and 100 microns, simulates an equivalent of 80A shore durometer hardness. post Cure cycle is required for this product undertaken by Devanét® for our customers.

SURGICAL GRADE RESIN This special resin was used by Devanet to develop medical applications, notablly naso pharanygeal swabs for PCR tresting. Gaining FDA approval this resin is used by our medical company Devmedico for use where hypo allergenic materials are required and meet obligations for Gamma, Ethlyene Oxide and other radiation sterilisation. Devanet can design and produce nasal swabs, swabs for Veterinary and Cosmetic appications as well as other products for use in the NHS.

Special UV curing is applied to some products to ensure that the resulting product reaches its maximum strength and is suitable for handling. This is an automated process provided by Devanét®. |

||||||||||||||||||||

NEBULISED AEROSOL POLISHING TECHNOLOGY

|