ceramic coating - nano particlate E coating

|

| The fabulous nano ceramic protective coating for all precious metals |

Devanét® has invested over the past 5 years in a nano Ceramic coating systems to enhance the properties of buckles, jewellery and metal gifts. Coded as Ceramic E coat, is ideal for fashion, corporate, promotional and retail gifts in jewellery as it guarantees a protective layer against tarnishing and provides a strong resistance to abrasion, corrosion, swear and is hypo allergenic. It is the most robust coating available that we know off that has test results to back up the performance and proven results with customers throughout the world.

One of the additional benefits to the jewellery and component market for fashion accessories is that the coating we apply is Hypo Allergenic and therefore suitable for people with metal allergies. With a coating weight from 5 to 35 microns the finish does not detract from the liminosity of the metal and is is fact translucent so the lustre shines through.

SOME POINTERS FOR OUR CUSTOMERS Devanet undertake the ceramic coating inhouse from start to finish, there are some important notes for our customers.

Hanging All the products we apply coating to must be suitable for hanging or hollow so we can place an fixure on the inside to support to product. A very thin wire is fixed to the item but even with extreme care it is likely a small witness mmark will be evident after coating. In most cases it is hidden as the wire is mounted to customers agreement in an area where the mark cannot be seen.

Engraving and design We always recommend that we engrave or CNC logos or designs before coating as the engraving with diamond tools or laser will penetrate the coating.

The process It is a complicated process and to doa good job takes approximately 2 hrs per item from start to finish and the items must be able to withstand up to 160c for an hour.

Finish supplied The products must be supplied mirror polished and clean, we do offer a poilishing and cleaning service and a masking service if required.

Not suitable Chains - unfortunately not all chains are suitable as they tend to stick together Pearls which are mounted Semi precious stones or gems that cannot withstand 160c for 1hr. Scratched or damaged articles

LAB MIXING NEW COLOURS Altought the standard colours areare just 22 including clear, our new lab mixing capability will be able to mix other colours on demand for customers. This new facility has already been implemented in our 2k ceramic and is now being rolled out for the nano ceramic range. If you require a special nano ceramic colour let us know and we will see if we can hekp you.

This technology opens up opportunities from the traditional plating and polishing of Pewter to exciting performance benefits with just a clear coat, or colours with stunning finishes and it works on most metals but expecially polished versions. Fior matt and other opaque colours use our 2k ceramic.

Ceramic coatings are used in the automotive industry and are equally at home in marine environments, examples are our D rings, buckle and other metal components that have been coated for applications including crew clothing, racing teams, aircraft maintenance and other corporate applications. Devanet will design and offer a cost effective coating solution for any of our metal products. For example our 2k ceramic coating outlasts stainless steel for corrosion.

The decorative elements and ability to custom ceramic coat in colour and to offer a range of colours to jewellery, fashion accessories and buckle components opens up wide ranging possibilities for customers, with a combination of standard colours other mixed varieties are possible, just ask the factory and specify a RAL colour or if in doubt a Pantone solid coated colour and we will try and get a as close a match as possible for you.

Devanet can offer a complete coating service for small or large volumes of components or buckles, prices are based on the overall sisze of the object to be coated in sq cms and the coating thickness required.

Extensively tested against various chemicals, abrasion, UV and elements that can affect the performance and tarnishing of metals that have been plated or are in their natural state.

Devanet are the onky UK company to provide totally integrated services for ceramic coatings of jewellery, flocking, powder coating, electro plating and other plating and coating services inhouse at our factory in Cheshire. |

|

|

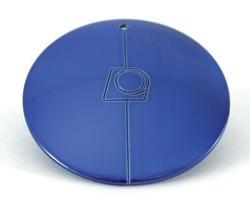

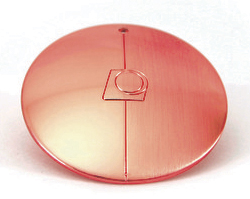

| Solid brass - nickel - 24 carat gold - ceramic | Solid brass mirror polished - clear ceramic |

|

|

| Jewellery clear finish | Oxhead charm & buckle Rose finish |

|

|

Gold to silver coloured Buckle |

Clear Anti Tarnish Ceramic Coating |

|

|

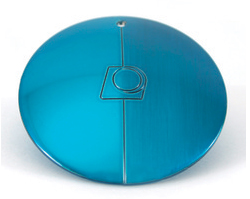

Ceramic Turquoise coated buckle |

Ceramic Coated Screws |

|

|

| Ceramic - Turquoise | Ceramic - Cerise |

|

|

| Ceramic - Yellow on solid brass | Cast egg and white ceramic |

|

|

| Ceramic - Gunmetal Fnish | Finished Components |

|

|

Ceramic Coating of metals with a matt finish |

|

Devanet's Ceramic coating or electrophoretic deposition (EPD) coating system is a method which uses electrical current to deposit the coating. It is a process in which a metallic substrate is submerged into a water-based solution containing a special blend of materials. Voltage is applied to the part causing the blend to condense onto the part. The substrate is then coated wherever it comes into direct physical contact with the liquid granting 100% coverage of complex parts. The Ceramic coating system installed by Devanet can be used for both technical and decorative finishing applications. From the decorative view, pigments can be added to the coating allowing for an unlimited number of colors to be realized and then replicated onto metal. On the technical side the Ceramic coating in its transparent or clear form provides an extreme protection to corrosion, oxidization, and abrasion when used as a topcoat, this is ideal for jewellery and unteated metals. The Ceramic coating can also be used as a primer for subsequent other coating steps. Recent advancements in nano-technology have put forth new options in coating systems that help to supersede in what are classified as more traditional e-coating systems. Nano-ceramic particles can now be incorporated with the coating material maximizing the benefits in corrosion protection and abrasion resistance. These hybrid systems represent the new frontier in electro-coating and Devanet is working with the developers of this process to enhance the potential in the jewellery and other industries which would benefit from the decorative and technical benefits of Ceramic Coating. Special colours can be created subject to minimum volumes of 100 plus buckles or components. |

|

|

|

Aqua Ceramic Coating |

18 Carat Gold Ceramic Coating |

|

|

Emerald Green Ceramic Coating |

24 Carat Gold Ceramic Coating |

|

|

Jet Black Ceramic Coating |

Black Ceramic Coating |

|

|

Chocolate Brown Ceramic Coating |

Royal Blue Ceramic Coating |

|

|

Copper Ceramic Coating |

Pink Ceramic Coating |

|

|

Rose Gold Ceramic Coating |

Red Ceramic Coating |

|

|

Rhodium Ceramic Coating |

Turquoise Ceramic Coating |

|

|

Transparent Clear Ceramic Coating |

White Ceramic Coating |

|

|

Maroon Ceramic Coating |

Fuchsia Ceramic Coating |

|

|

Violet Ceramic Coating |

Lemon Ceramic Coating |

|

|

Green Ceramic Coating |

Orange Ceramic Coating |

| OTHER COLOURS MADE TO ORDER ASK FOR OUR NANO CERAMIC LAB MIXING SERVICE | |

|

| NANO CERAMIC TEST RESULTS |